HDPE CNC Machining

HDPE is a thermoplastic resin generated by copolymerization of ethylene, in the form of white powder or granules, colorless and five toxic, the full name of high-density polyethylene. Compared with low-density polyethylene (LDPE), HDPE has a higher density and higher melting point, so the mass is lighter, but more rigid, durable and high strength.

HDPE materials have good mechanical strength and chemical resistance, and are often made into containers for industrial parts, medical supplies, consumer electronics and other industries in CNC machining services.

HDPE Material Properties

Understanding the properties of HDPE materials is very useful for both product prototyping and production. Tuofa machinery designers can help you choose the most suitable material, design better quality products and reduce the technical risks in the production process.

Try Tuofa Now!

Our engineers understand the processing properties that HDPE material has and will apply it wisely in various projects and custom parts. China Tuofa is committed to providing you with the best HDPE application solutions to get your project done while reducing your input costs.

HDPE Material Properties

| NOMINAL PHYSICAL PROPERTIES | ASTM | UNIT | VALUE |

| Density | D1505 | g/cm3 | 0.953 |

| Melt Index, Condition 190 °C/2.16 kg | D1238 | g/10min | 0.02 |

| Condition 190 C/5.0 kg | 0.14 | ||

| Condition 190 C/21.6 kg | 25 | ||

| ESCR Condition B, (100% lgepal), Fs |

D1693 | h | 300 |

| Tensile Yield Strength, 50 mm/min | D638 | MPa | 27 |

| Elongation at Break, 50 mm/min | D638 | % | >600 |

| Brittleness Temperature | D746 | °C | -75 |

| Flexural Modulus, Tangent | D790 | MPa | 1300 |

| Shore D Hardness | D2240 | 63 |

HDPE Uses

CNC machined HDPE materials are used in various fields such as machinery, industrial equipment, automation equipment, electronic equipment, bicycles, automobiles, medical equipment, etc., further enhancing the value of HDPE plastic applications.

Bearings: motors, robots, hand tools, etc. Used to support and position the rotation of the shaft and reduce the friction between the shaft and the housing.

Bearings: motors, robots, hand tools, etc. Used to support and position the rotation of the shaft and reduce the friction between the shaft and the housing.

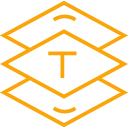

Sliders: sliding doors, sliding windows. Used to support and position the sliding of doors or windows, ensuring stability and smooth sliding of the device.

Sliders: sliding doors, sliding windows. Used to support and position the sliding of doors or windows, ensuring stability and smooth sliding of the device.

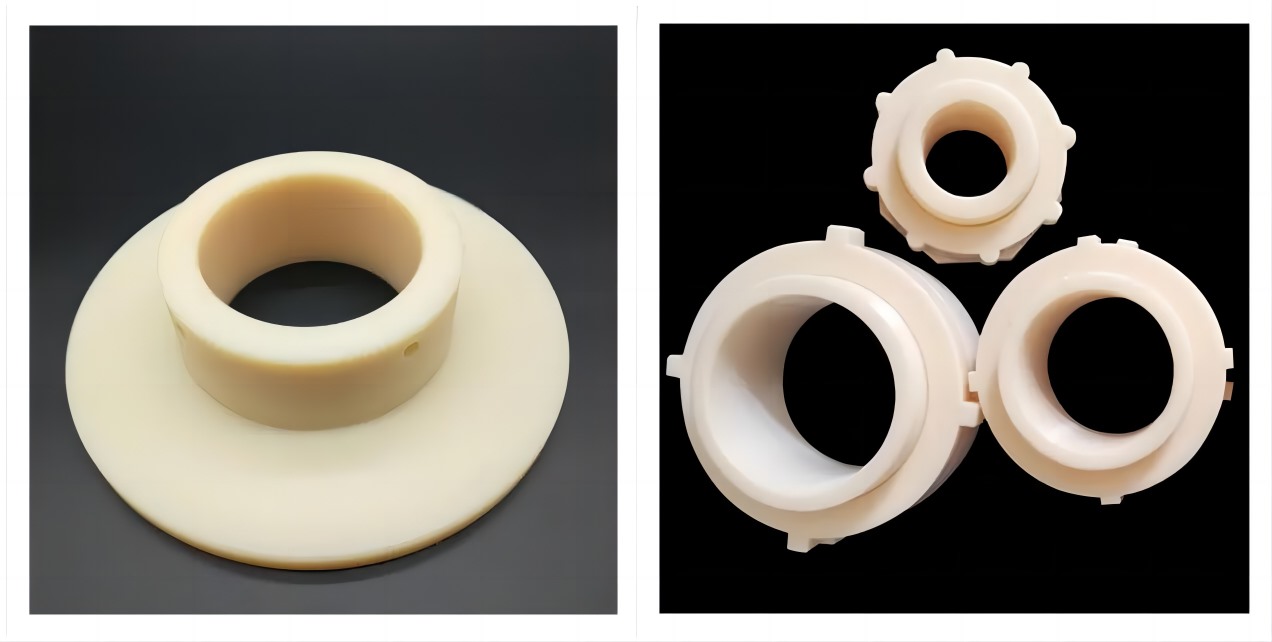

Parts gasket: used on mechanical equipment and industrial pipelines , used to fill or support the gap between two or more parts to achieve sealing, isolation vibration, compensation pressure, etc.

Parts gasket: used on mechanical equipment and industrial pipelines , used to fill or support the gap between two or more parts to achieve sealing, isolation vibration, compensation pressure, etc.

Seals: used in pipelines, valves, pumps and other liquid transmission equipment, the same as parts of the gasket is to prevent leakage of liquid or gas, and to ensure the normal operation of the equipment.

Seals: used in pipelines, valves, pumps and other liquid transmission equipment, the same as parts of the gasket is to prevent leakage of liquid or gas, and to ensure the normal operation of the equipment.

Precision parts: such as gears, nuts, bolts, used to transmit power and speed or used in connection devices, accuracy and stability is essential for the normal operation of the equipment

Precision parts: such as gears, nuts, bolts, used to transmit power and speed or used in connection devices, accuracy and stability is essential for the normal operation of the equipment

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home