Delrin CNC Machining

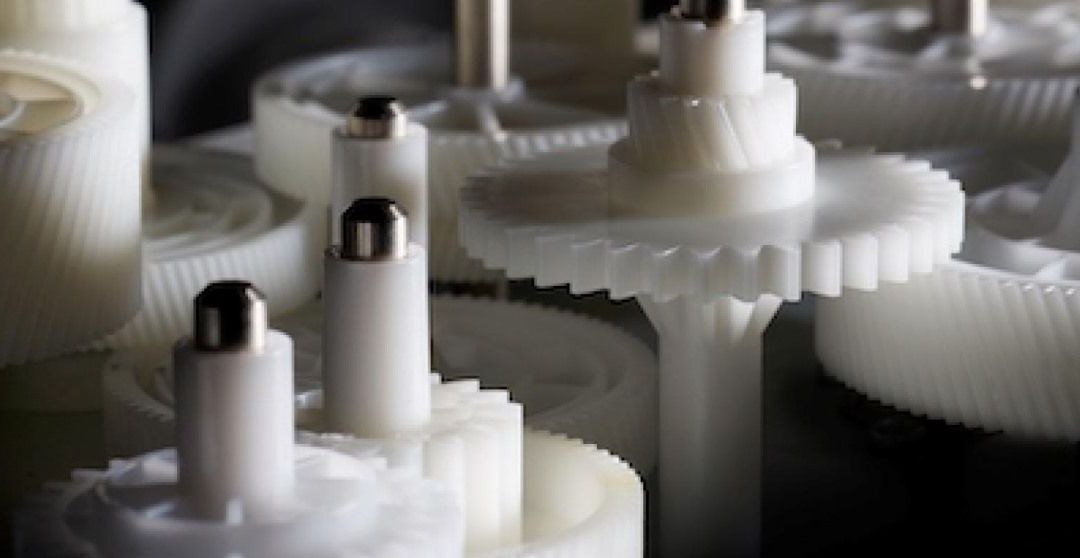

Delrin is a smooth and glossy material that is light yellow or white in color. It is also known as POM or Acetal. It can be used long-term within a temperature range of -40 to 100°C and is ideal for high-load mechanical applications such as gears, safety belts, conveyors, medical injection devices, and other products and components with strict requirements. Delrin is the perfect material for designers looking to replace metal components.

Delrin parts play an important role in CNC plastic machining services, and Tuofa has been researching and innovating the manufacturing process of delrin parts for 17 years.

Delrin Plastic Properties

Try Tuofa Now!

Welcome to tuofa, we are the top Delrin plastic CNC machining factory in China. We can meet your requirements from design to production, and we have established a good reputation in the global market for custom parts.

About Delrin Performance

As a high-performance engineering plastic, Delrins have many excellent performance, including high strength and stiffness, wear resistance, and chemical resistance. It is mechanically stiffer and stronger than other engineering plastics, and remains strong at low and high temperatures.

| Performance | Units | Value | Test standards |

| Tensile modulus | MPa | 3400 | ISO 527-1/-2 |

| Yield stress | MPa | 74 | ISO 527-1/-2 |

| Elongation at yield | % | 12 | ISO 527-1/-2 |

| Flexural modulus | MPa | 3200 | ISO 178 |

| Bending stress (3.5% strain) | MPa | 85 | ISO 178 |

| Density | kg/m³ | 1420 | ISO 1183 |

Delrin Applications

Because of its excellent properties, Delrin is used in a wide variety of applications in machinery, automotive, medical devices, and various other fields. Delrin can meet the needs of different scenarios and earn the trust of consumers. When CNC machining custom parts, choosing Delrin materials can provide better performance and quality for customers' projects.

In the automotive industry: manufacture of automotive pumps, carburetor parts, oil pipes, power valves, universal joint bearings, motor gears, crankshafts, handles, instrument panels, car window lift devices, electric switches, seat belt buckles, etc.

In the automotive industry: manufacture of automotive pumps, carburetor parts, oil pipes, power valves, universal joint bearings, motor gears, crankshafts, handles, instrument panels, car window lift devices, electric switches, seat belt buckles, etc.

Machinery manufacturing industry: widely used as gears, drive shafts, chains, valves, valve stem nuts, bearings, cams, impellers, rollers, nozzles, guides, bushings, pipe joints and mechanical structure parts and other transmission parts.

Machinery manufacturing industry: widely used as gears, drive shafts, chains, valves, valve stem nuts, bearings, cams, impellers, rollers, nozzles, guides, bushings, pipe joints and mechanical structure parts and other transmission parts.

For electrical and electronics, household appliances: manufacture of plugs, switches, buttons, relays, washing machine pulleys, shafts and wheel housings for cassette tapes, and electronic computer housings.

For electrical and electronics, household appliances: manufacture of plugs, switches, buttons, relays, washing machine pulleys, shafts and wheel housings for cassette tapes, and electronic computer housings.

For precision instruments: support frames for manufacturing shelves, hoods, friction pads and parts for other precision instruments such as clocks and watches, cameras, etc.

For precision instruments: support frames for manufacturing shelves, hoods, friction pads and parts for other precision instruments such as clocks and watches, cameras, etc.

Corrosion-resistant consumer goods: fire taps, pen sticks and pen sleeves for fountain pens, toys, figures, zippers, eyelash oil sticks, etc.

Corrosion-resistant consumer goods: fire taps, pen sticks and pen sleeves for fountain pens, toys, figures, zippers, eyelash oil sticks, etc.

People Also Ask

POM plastic machining feeds and speeds

When machining POM material, the chuck should be clamped with as little force as possible, and it must be cooled, and the coolant should be twice as much as usual. High speed tool steel tools are used and the cutting edge must be sharp. Feed 9000, speed 15000, cutting 10mm per tool. |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home