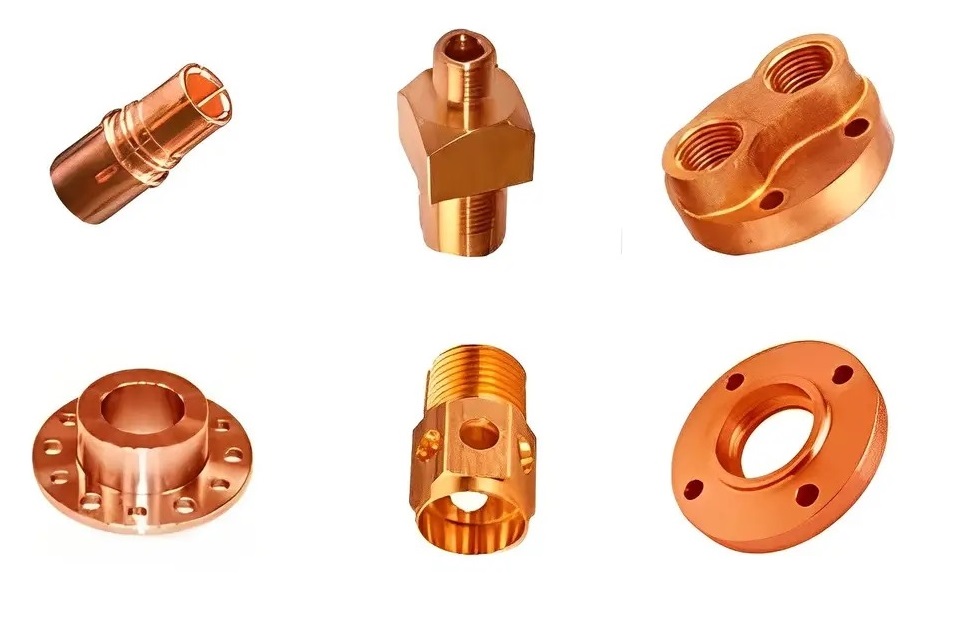

Copper CNC Machining

Copper is rose red and purple after the formation of oxide film on the surface, copper is second only to silver in electrical conductivity and thermal conductivity, widely used in the electrical industry, motor manufacturing, energy industry, ship propellers, etc., but the strength and hardness is poor.

We understand that each project is unique and these copper parts are custom made to your specifications. Let our copper CNC machining engineers help you craft your vision with precision and professionalism.

Copper Machinability

Copper is so ductile that a drop of copper can be stretched into 2 km of copper wire or pressed into a bed of clear copper foil.

| Application | Various transmission parts and fixed parts, such as cylinder sleeves, connectors, fasteners, gears, twisting and turning parts, etc., all need to copper or copper alloy to reduce wear and lubrication. |

| Advantages | Electrical conductivity, thermal conductivity, corrosion resistance and good processing properties. |

| Disadvantages | CNC machining copper parts in the environment containing active substances are prone to corrosion. |

| Lead Time | Prototype parts delivery time is 1-3 days, mass production depends on the specific quantity, we have additional expedited processing services to meet your needs. |

| Price | $$$ |

| Tolerances | Can be achieved high precision tolerances of 0.0004" (0.01mm) |

| Design for Manufacturability | Before copper can be machined, design requirements and specifications must be sorted out, which contribute to the functionality of copper components. These include reducing the number of part setups, dimensional checking, and preventing deep cavities with small radii. |

Copper 101

Copper 101 is oxygen-free copper, copper purity of 99.99%, oxygen content of not more than 0.0005%, the corresponding metal grade in China is TU0 oxygen-free copper.

Application: CPU heat sink, vacuum seal, transistor component, glass metal seal, printed circuit board, connector material, etc.

Application: CPU heat sink, vacuum seal, transistor component, glass metal seal, printed circuit board, connector material, etc.

Features: high purity, fine organization, very low oxygen content, no pores, trachoma, cracks, impurities, excellent electrical conductivity.

Features: high purity, fine organization, very low oxygen content, no pores, trachoma, cracks, impurities, excellent electrical conductivity.

Copper 101 Physical Properties

| Density | Modulus of Elasticity | Poisson's Ratio | Conductivity | Thermal Conductivity | Thermal expansion coefficient | Electrical Conductivity |

| 8.94 g/cm3 | 115 GPa | 0.34 | 58.6 MS/m | 391 W/(m.K) | 17.7 10-6/K | 101% IACS |

Copper 101 Mechanical properties

| State | Tensile Strength | Elongation at Break(A11.3,%) | Vickers hardness |

| M 060 | ≥195 | ≥30 | ≤70 |

| Y4 H01 | ≥215-275 | ≥25 | 60-90 |

| Y2 H02 | ≥245-345 | ≥8 | 80-110 |

| Y H04 | ≥295-380 | ≥3 | 90-120 |

| T H06 | ≥350 | ≥110 |

Try Tuofa Now!

Are you looking for a reliable partner for brass processing? From prototyping to production, get excellent results every time with Tuofa's fast and efficient brass CNC machining services!

Copper 102

Copper 102 also belongs to oxygen-free copper, copper purity of 99.97%, oxygen content of not more than 0.003%, the corresponding metal grade in China is TU1 oxygen-free copper.

Applications: switchgear, transformers and other electrical equipment and heat exchangers, pipes, solar heating devices such as flat plate collectors and other heat-conducting equipment.

Applications: switchgear, transformers and other electrical equipment and heat exchangers, pipes, solar heating devices such as flat plate collectors and other heat-conducting equipment.

Copper 102 Physical Properties

| Density | Modulus of Elasticity | Poisson's Ratio | Conductivity | Thermal Conductivity | Thermal expansion coefficient | Electrical Conductivity |

| 8.94 g/cm3 | 196 GPa | 0.34 | 58.6 MS/m | 391 W/(m.K) | 17.7 10-6/K | 100% IACS |

Copper 102 Mechanical properties

| State | Tensile Strength | Elongation at Break(A11.3,%) | Vickers hardness |

| M 060 | ≥205 | ≥20 | ≤80 |

| Y4 H01 | ≥230-290 | ≥15 | 70-100 |

| Y2 H02 | ≥255-350 | ≥5 | 90-120 |

| Y H04 | ≥325-400 | 100-140 | |

| T H06 | ≥370 | ≥120 |

The 3 best ways to milling copper

The material of copper is soft, and it is easy to be hot during the milling process with fast heat conduction, and it will also produce burrs. |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home