Metals 3D Printing

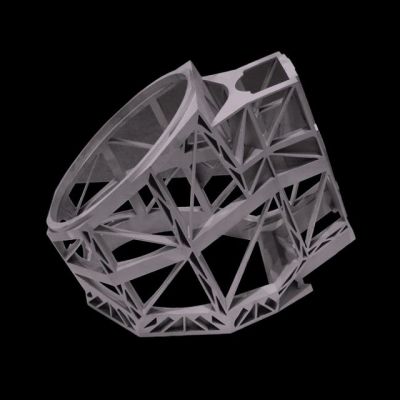

Introducing the newest way to print metal parts! With metal 3D printing, you can create durable, high-quality parts without having to invest in expensive equipment. Our 3D printers use lasers to fuse metal powders or mixed wire together, creating parts with intricate details and smooth surfaces.

The right implementation of metal 3D printing can dramatically improve business efficiency and agility - whether by eliminating the need for design drawings and machine processing, or by dramatically shortening the delivery cycle of the product development process.

Tuofa can help your organization successfully implement metal 3D printing technology with the specific business benefits and technological advantages you will gain.

A Guide to Custom 3D Printed Parts in Metal Materials

There are a few things to consider when choosing the right metal material to create 3D printed parts:

Tuofa Precision Machining Shops provides online engineering customer support for your parts, 2D and 3D drawing design, and manufacturing questions. Assist in reviewing project plans; this includes case-by-case suggestions to help you reduce costs early on in the design process. 100 CNC machines for online CNC precision machining parts, making it an excellent choice for parts prototype design and low to high-volume production runs, instant CNC parts quotes, on-time delivery, 30+ materials and 10+ surface finishes for tolerances down to 0.01mm.

3D Printing Metals Parts Quote

3D Printing Metals

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances:±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

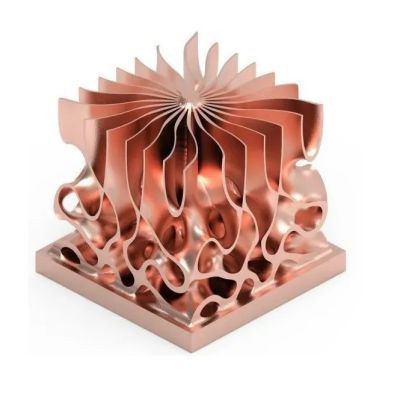

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

- Price: $$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size:200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

- Price: $$$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Why Choose Metal 3D Printing Service

A few years ago, 3D printing with metal was only used for industry. That's all changed now that metal 3D printing is available on desktop FDM 3D printers and more specialized machines that not only produce high quality parts, but are also more affordable.

High Precision

At present, the precision of Tuofa's metal 3D printing equipment is controlled at 0.05mm, so that the products or parts can achieve higher stability and complexity.

Short Cycle Time

Metal 3D printing without mold making process, making the production time of the model is greatly shortened, generally a few hours or even a few minutes to complete a model of printing.

Personalization Can Be Realized

There is no limit to the number of models that can be printed by metal 3D printing, whether one or more can be produced at the same cost.

|

Try Tuofa Now!

Tuofa Engineer Support Team - Real human quotes are more accurate than software quotes

|

The 10 Best Methods for Metal 3D Printing

Almost any metal can be 3D printed. Aside from the complexity and speed of the part, one of the main advantages of 3D printing metals is the savings in raw materials and almost no waste. This is extremely important when printing with expensive materials, such as titanium.

Some 3D printing methods can use materials that are already used for injection molding, such as some powders, wires and pellets, while other materials are uniquely formulated for 3D printing. If you know what material your part needs to be printed in, check out the guide below to help you understand all the methods that can be used to print titanium, aluminum, and steel.

| Type of Technology | Forming Size | Cost | Minimum Layer Height | Part Performance | Printing Speed |

| FDM/Extrusion | Small to Medium | $ | 0.05 mm | Medium to High | 500 mm/s |

| SLM/PBF | Small to Medium | $$$ | 0.02 mm | High Quality | 25 cm³/h |

| EBM/PBF | Small to Medium | $$$$ | 0.07 mm | High Quality | 55 – 80 cm³/h |

| Metal Binder Jetting | Small to Medium | $$$ | 0.035 mm | High Quality | 1,500 cm³/h |

| WAAM | Large to Very Large | $$ | 1 mm | High Quality | 2.2 kg/h |

| DED Laser | Medium to Large | $$$$ | 0.2 mm | High Quality | 500 cm³/h |

| DED eBeam | Medium to Large | $$$ | 0.2 mm | High Quality | 2,000 cm³/h |

| Metal Lithography | Very Small to Medium | $$$$ | 0.01 mm | High Quality | Up to 300 floors/h |

| Cold Spray | Medium to Large | $$ | 0.38 mm | High Quality | 100 g/m |

| Micro 3D Printing | Very Small | $$$$ | 0.005 mm | High Quality |

Tuofa Precision Machining Shops provides online engineering customer support for your parts, 2D and 3D drawing design, and manufacturing questions. Assist in reviewing project plans; this includes case-by-case suggestions to help you reduce costs early on in the design process. 100 CNC machines for online CNC precision machining parts, making it an excellent choice for parts prototype design and low to high-volume production runs, instant CNC parts quotes, on-time delivery, 30+ materials and 10+ surface finishes for tolerances down to 0.01mm.

Get an Metal 3D Printing Quote

People Also Ask

what metals can be 3d printed?

Metals that can be 3D printed include aluminum, steel, stainless steel, copper, cobalt chrome, titanium, tungsten and nickel-based alloys. Is 3d printed metal strong?

Yes, 3D printed metal is strong and durable. Depending on the type of metal used, 3D printed metal can be as strong as traditionally machined metal parts. Is metal 3d printing expensive?

Metal 3D printing can be expensive depending on the type of metal used and the complexity of the design. However, it can be more cost-effective than traditional manufacturing methods in certain cases. Is 3D printed metal stronger than forged?

It depends on the type of metal used and the complexity of the design. Generally, 3D printed metal is as strong as traditionally machined metal parts, but it can be stronger than forged metal in certain cases. How metal 3d printing works?

Metal 3D printing is a process of creating three-dimensional objects from a digital file. It works by using a laser to melt and fuse metal powder layer by layer, creating a solid object. |

Online Metals 3D Printing Resources

What Is CNC Turning

CNC turning is the process of removing material from a rotating workpiece using the linear path of tools on a CNC lathe. In a simple perspective, the main elements involved in this process are the rotating spindle in which your work part is clamped and the cutting tool that is mounted on a turret.

Learn More

A Method for Calculating the Cost of Turned Parts

At present, the online CNC machining shop is widely used in the machinery industry, and it is inevitable to encounter some complex, special-shaped or similar hollow workpieces. When making such workpieces, it is a test of the experience and technology of the program and the machinist.

Learn More

CNC Machining Complex Cavity Parts

At present, the online CNC machining shop is widely used in the machinery industry, and it is inevitable to encounter some complex, special-shaped or similar hollow workpieces. When making such workpieces, it is a test of the experience and technology of the program and the machinist.

Learn More

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home