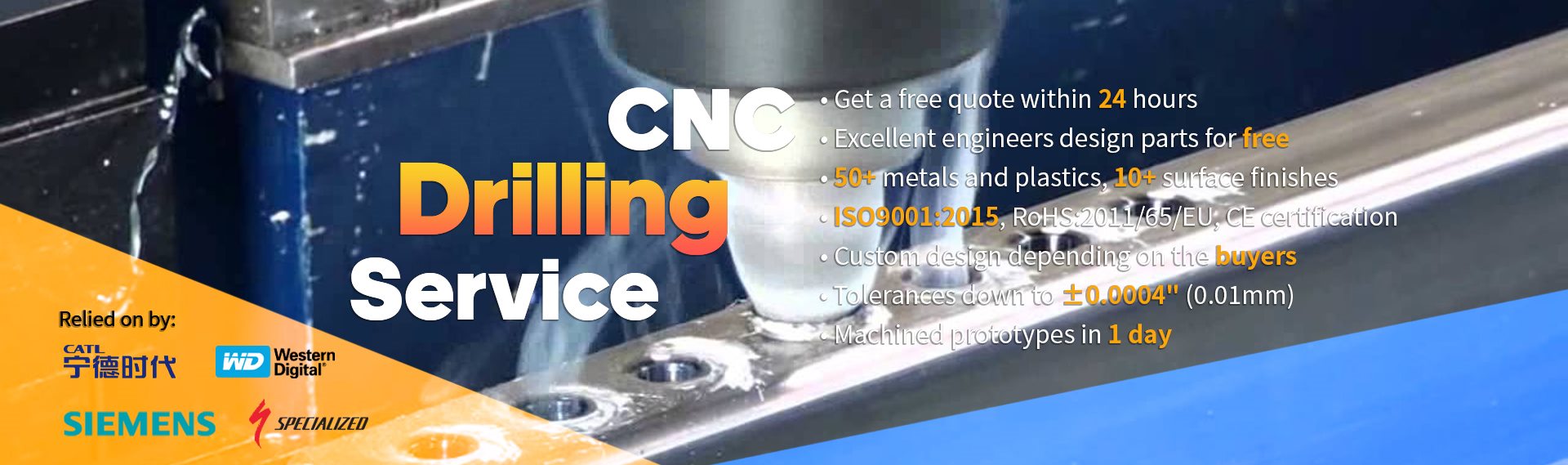

Advanced CNC Drilling Services for Global Markets

CNC drilling service is mainly used for drilling, reaming, chamfering and other processing. CNC drilling services are currently mainly used in the automotive, mould, shipbuilding, aerospace, and construction machinery industries, especially for some hardware parts with multiple holes that need to be processed. Of course, the precision CNC drilling shops small batch CNC machining service is also suitable for startups and designer teams, speeding up the time to market.

Although CNC drilling technology has been carried out in the global market for more than ten years, with the continuous development of mechanical automation, the CNC drilling service market has not only not decreased, but has become more and more popular so what advantages do CNC drilling services have so attractive?

Online CNC drilling Services-Low Cost On Demand Manufacturing, On-Time Delivery

1. The traditional drilling service can only process some relatively simple and flat parts. In contrast, the CNC drilling service can process highly complex parts, such as complex curved and three-dimensional space surface parts, which is suitable for CNC drilling machines. Strong performance and flexibility are inseparable.

2. CNC drilling has high machining accuracy and stable quality. It only needs to do the workpiece clamping and positioning work at one time, and the parts can be automatically processed in multiple processes, which helps enterprises to improve production efficiency and save a lot of labour costs...

3. CNC drilling service has good impact, toughness, hardness, and wear resistance and can drill, tap, and mill parts for a long time, so it is also called a multi-functional CNC drilling service

Precision CNC Drilling Experience in Numbers

|

|

|

|

| 2000+ | 2M+ | 60+ | 17+ |

| Companies served | CNC parts produced | Countries shipped | Years in business |

Precision CNC Drilling Services - One of the Best CNC Machining Manufacturers in China

With the improvement of modern processing technology, the technological requirements of CNC drilling are becoming more and more refined, and the performance requirements of machine tools are also constantly improving.

Tuofa CNC machining adopts a vertical deep-hole drilling machine to process components with higher precision, fast processing efficiency, and stable batch processing.

- The maximum width of six-sided processing can reach 1200mm, and the minimum processing width is 50mm

- Advanced path optimization algorithm for efficient six-sided drilling and slotting milling

- Perfect docking with more than 30 design software around the world to achieve rapid processing

Tuofa CNC Drilling Services Capabilities

Precision CNC drilling features

high rigidity

The structure is upgraded, more stable, more excellent in quality, more efficient, and more accurate.

High stability

Stable batch processing, low tool wear and long-lasting durability

High precision

High aperture precision, accuracy up to ±0.01mm

high speed

The processing speed is fast, and the time is 1/15 of the traditional wire cutting.

high quality

The processed product has a precise aperture and a smooth hole wall.

High automation

The equipment adopts numerical control, realizes one-key processing, and the operation is simple and convenient.

As one of the best CNC machining manufacturers in China, Online CNC Milling Machining For 50 CNC Machine, making it an excellent choice for rapid prototyping and low to high volume production runs, instant CNC parts quotes, low-cost on-demand manufacturing, 50+ materials Perfect and 10+ surface finishes for tolerances down to 0.01mm.

Get an Instant CNC drilling Quote

Surface Treatment of CNC Machining Services

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

- POM

- Nylon

- ABS

- PEEK

- PTFE

- PC

- HDPE

- PVC

- PMMA

- PET

- PP

Metal |

Application of Metal |

|

Aluminum; Aluminum 6061, Aluminum 5052 |

Learn more about aluminum CNC Machining |

|

Copper; Copper 101, Copper C110, Copper 260 (Brass) |

Learn more about copper CNC Machining |

|

Bronze; Bronze 220, Bronze 510 |

Learn more about bronze CNC Machining |

|

Stainless steel; Stainless steel 301, Stainless steel 304, Stainless steel 316/316L |

Learn more about stainless CNC Machining |

|

Steel;Steel 1018 (Low Carbon) |

Learn more about steel CNC Machining |

Tuofa CNC Machining Materials

Get your materials and tooling faster and at lower prices with Tuofa machining.

Ceramics

Glass

Metal

Plastics

Rubber

Wood

Available Surface Finishes for Tuofa CNC Drilling

Looking for metal stamping suppliers? You can choose a wide selection of metal surface finishing services after machining at Tuofa CNC machining manufacturer to improve the parts appearance, surface smoothness, corrosion resistance and other performance of your CNC machined parts.

- Painting: refers to an altering surface finishing process, spraying paint, pigment, or color to a solid surface as a colored protective layer, and can be done on metal or non-metal CNC machined components of any shapes, usually applied on aluminum, stainless steel, and steel alloy parts. The purpose is to improve aesthetic appearance and prevent corrosion or oxidation.

- Passivation: a common chemical surface treatment method for steel and stainless steel, to remove ferrous contaminants or use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity.

- Electroplating/Plating: a process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the machining metal surface or build up thickness for undersized parts.

- Powder coating/Powder coat: a functional and decorative finish, which is applied as a free-flowing, dry powder, employs electrostatically and then cured under heat, to create a hard finish that is tougher than conventional paint. The main applications include household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts.

- Anodizing/Anodized: an electrolytic passivation process of forming a thin layer of aluminum oxide on the exterior of aluminum CNC machined parts to increase the thickness of the natural oxide layer and protect the metal, as the layer has higher corrosion and abrasion resistance than aluminum.

More Custom Metal Finishing Service for Presenting the Best Effect of Your Parts

- Black oxide: also known as blackening, gun bluing, or hot blackening, a chemical process of forming a black conversion coating on stainless steel, copper and copper-based alloys, zinc, powdered metals, silver solder, and ferrous materials, to improve corrosion resistance and minimize light reflection.

- Conversion coating: also known as chromate conversion, the coating is used for metals converted to a protective layer through the chemical or electrochemical processes, primarily used as a corrosion inhibitor, decorative finish, or to retain electrical conductivity.

- Bead blasting/Bead blast: the process of removing surface deposits by applying fine glass beads at high pressure without damaging the surface.

- Abrasive blasting/sandblasting: the process or operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system, to remove surface contaminants, clean metals, or increase a texture, then change the smoothness or roughness of a surface.

CNC Machining Tolerance

Feature |

Description |

|

Maximum Part Size |

Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter. |

|

Standard Lead Time |

3 business days |

|

General Tolerances |

Tolerances on metals will be held to +/- 0.005" (+/- 0.127 mm) by ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”. |

|

Precision Tolerances |

Tuofa can manufacture and inspect tight tolerances per your drawing specifications including GD&T callouts. |

|

Minimum Feature Size |

0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

|

Threads and Tapped Holes |

Tuofa can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

|

Edge Condition |

Sharp edges are broken and deburred by default |

|

Surface Finish |

The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

Industries of CNC Drilling Applications

CNC machining parts are all around you, they may be important components of your car and also can perform vital functions in your electrical equipment. Tuofa is an accomplished CNC supplier that engaged in a broad range of CNC machining applications.

Electronic Industry

Medical Industry

Automotive Industry

Agricultural industry

Machine tool industry

Aerospace industry

Advantages of Tuofa CNC Machining Services

- Efficient CNC machining factory for mass production rapid prototyping service

- Average 10 days turnaround time and 99.88% on-time delivery

- Multiple options of machining materials to meet specific properties.

- Fast free quotation within 24 hours after inquiry

- Have high customer satisfaction and loyalty

- Rich design and manufacturing experience

If you are looking for quality CNC machining services near me, our low-cost CNC custom machining will review the design, build your quote, assess the cost, and get your non-metal or metal fabrication parts into production orderly and efficiently.

What Is CNC Drilling & How CNC Drilling Works

Drilling is the cutting process in which the workpiece does not move, making the cutter move, aligning the cutter center with the hole center, and making the cutter rotate. CNC Drilling is primarily done on CNC machines including CNC milling machines and lathes. CNC drilling service produces round holes, typically for machine screws and bolts. Drilling can process CNC drilling parts with metals, hard plastics, wood and, most other rigid materials. There are several types of drilling machines available for CNC, including these drill presses: Upright, Bench and Radial. When in use, the step-by-step process for CNC drilling includes:

- The operator uploads and accesses the computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

- The operator installs the appropriate drill bit and secures the designated material on the table.

- The operator starts the drilling process through the control panel or interface.

- The spindle lowers, drilling the appropriate hole sizes and diameters.

Tuofa is an ideal choice if you are seeking the best CNC machining shop or CNC machining manufacturer for the fabrication of small, medium, large-sized products in low volume or mass production. Our exceptionally trained and experienced employees fabricate components in accordant.

Get an Instant CNC drilling Quote

CNC Drilling Services For Precision Machine Parts – China CNC Drilling Parts Factory, Supplier

Establishing a centering mark or feature before drilling, such as by:

- Casting, molding, or forging a mark into the workpiece

- Center punching

- Spot drilling (i.e., center drilling)

- Spot facing, which is machining a certain area on a casting or forging to establish an accurately located face on an otherwise rough surface.

- Constraining the position of the drill bit using a drill jig with drill bushings

The surface finish produced by drilling may range from 32 to 500 microinches. Finish cuts will generate surfaces near 32 microinches, and roughing will be near 500 microinches.

High-precision:

High-precision:

The CNC drilling machine is controlled by a computer, which can automatically perform the image search of the camera within the recognition range, analyze it by computer, and then operate the materials to be drilled.

Easy to operate and use:

Easy to operate and use:

Using any kind of machine tool and simple use method can make the equipment popularize rapidly. The CNC drilling machine adopts a man-machine interface, and the working mode can be directly set on the computer interface through the touch screen.

Quick drilling:

Quick drilling:

Due to the fast response time of the CNC drilling machine, once the applicable mode is found, drilling can be carried out immediately to reduce drilling time, improve work efficiency, do not waste materials, and save resources.

Quality assurance Of Our CNC Drilling Services

- Tuofa precision CNC machining shop has passed ISO9001 certification

- Inspection report included in every order.

- Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Batch inspection in concurrence with ISO2859

- Strict NDA agreements with all Buyers

- Low-cost on-demand manufacturing, on-time delivery

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home