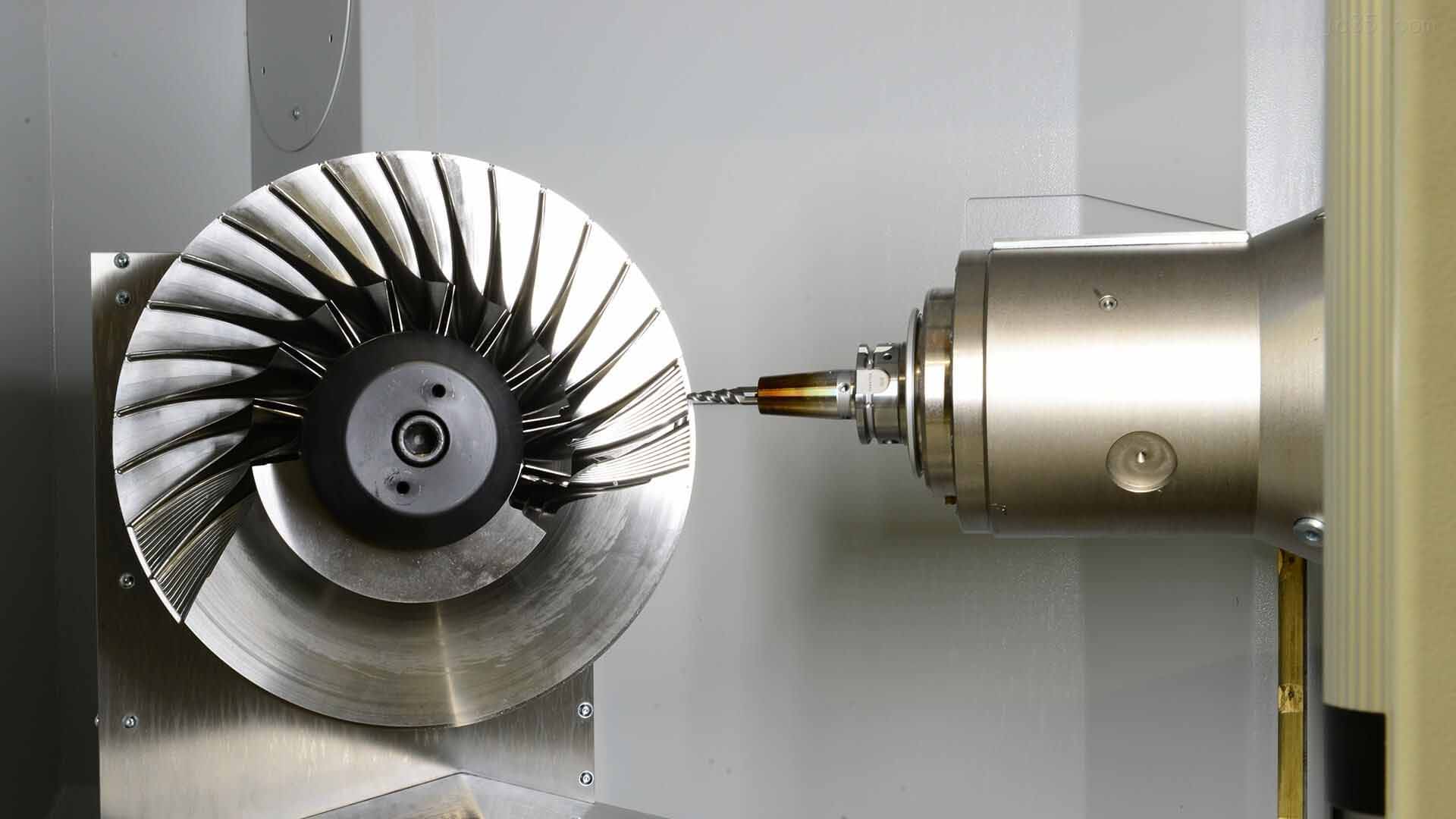

Online 5 Axis CNC Machining Services

5-axis machining is a more effective method for machining complex parts. As your CNC custom parts manufacturer, we ensure high-quality machined parts. Every order includes our standard inspection report. Further reports and certifications are available on request, submit an order to begin. Low-cost on-demand manufacturing and on-time delivery are the standards of our 5-axis CNC machining services. Extensive manufacturing capabilities to meet your production needs.

- Get a free quote within 2 hours

- 40+ metals and plastics, 10+ surfaces finishes

- Machined prototypes in 1 day

- Custom design depending on customer specs

Instant 5 Axis Machining Quote

Online Manufacturing Services-Low Cost On Demand Manufacturing, On-Time Delivery

Do you need on demand CNC machining? Tuofa precision machining shop has provided 5axis CNC machining & precision cutting services for 18 years, providing high quality, on-demand rapid manufacturing services for custom parts prototyping and product manufacturing.

Precision machining

Laser cutting, plasma cutting, waterjet cutting, bending, welding and stamping services

Instant Precision Machining Quote

Qualifications

Tuofa shares a continuous growth of 300%+ year-over-year annual growth. These are the features that make us stand out. Try our CNC machining on demand.

Quality Reports

For every order on our platform, we can provide a full list of quality reports according to customers’ requests. Including but not limited to:

- Inspection report

- Full dimensional report

- Material test report

Certificate

As a decade-experience on-demand manufacturing machining manufacturer, we provide commonly needed certifications, including but not limited to:

- ISO 9001:2015

- RoHS

- CE

First Article Inspection (FAI)

For low volume sheet metal parts and CNC machining orders that exceed 50 units or 5000 USD in the total price, the first article inspection is available on request.

Our experience in numbers

|

|

|

|

| 2000+ | 50000+ | 30+ | 18+ |

| Companies served | CNC parts produced | Countries shipped | Years in business |

5 Axis CNC Machining Services - Precision CNC Manufacturing Company with 5 Axis Machining Center

5-Axis CNC machining On-demand manufacturing High-quality finish, vast material options, and precise tolerances have made CNC lathe turning a favorable technology for serial production parts. Order CNC machined parts online.

Do you need precision CNC turning service? Tuofa transitioning to an on-demand manufacturing model gives Buyers more production flexibility. In Tuofa's precision machining workshop, our engineers and machinists can easily produce parts required by five axes in 5-axis machining service. No matter how complex CNC machining parts are, each step will be carried out with a rigorous attitude, providing excellent 5-axis machining components and demonstrating the highest quality standards. Tuofa machining manufacturer( www.tuofa-cncmaching.com) can meet your project needs.

Tuofa as one of China's best CNC machining is an ideal choice if you are seeking a CNC Machining Manufacturer or CNC Shop for the fabrication of small, medium, large-sized products in low volume or mass production. Our exceptionally trained and experienced employees fabricate components in accordance. As one of the best CNC machining manufacturers in China, Online CNC Milling Machining For 100 CNC Machine, making it an excellent choice for rapid prototyping and low to high volume production runs, instant CNC parts quotes, low-cost on-demand manufacturing, 30+ materials Perfect &10+ surface finishes for tolerances down to 0.005mm. Try our print on demand 3D.

Why Choose Tuofa 5 Axis CNC Machining Services

- Our five axis machining center adopts optimal and high-performance structural design, with machining accuracy of + / - 0.003mm

- We can use 3 / 4 / 5 axis machining centers including 30 kinds of materials such as aluminum, steel, copper, and titanium to process precision CNC products to meet different specifications.

- The complete process and strict quality control system evaluate the quality at each stage of our preparation, manufacturing, and inspection to ensure that the quality of 5-axis CNC machined parts always meets the requirements

- Now custom 5 axis milling machining parts with competitive prices, fast turnaround, improved productivity, and on-time delivery. Please also check our CNC machining milling service.

What is 5 Axis Machining?

5-axis machining belongs to Multiaxis machining. 5-axis machining is commonly used in industry in which the workpiece is translated linearly along three axes (typically x, y, and z) and the tooling spindle is capable of rotation about addition 2 axes.

There are now many CAM (computer-aided manufacturing) software systems available to support multiaxis machining including software that can automatically convert 3-axis tool paths into 5-axis tool paths. We also provide sheet metal prototype fabrication.

Benefits of 5 Axis Machining

- The amount of human labor is reduced if the piece would otherwise have to be turned manually during the machining.

- A better surface finish can be obtained by moving the tool tangentially about the surface (as opposed to moving the workpiece around the spindle).

- More complex parts can be manufactured, particularly parts with curved holes.

- Increased tool life due to the ability to achieve optimal angles between the tool and machining surface.

- Higher quality parts. What once required multiple setups now can be executed in only a few if not one, reducing steps and decreasing the opportunity for error.

- Shorten the R & D cycle of new products with our instant CNC machining quote.

- Shorten the production process and simplify production management.

5 Axis Machining vs 3+2 Machining

5-axis machining is different from 3+2-axis machining. 5-axis CNC milling or machining involves continuous adjustments of the cutting tool along all five axes to keep the tooltip optimally perpendicular to the part. 3+2 machining, also known as 5-sided machining or 5-axis indexed, is a 3-axis program with the cutting tool fixed at an angle depending on the two rotational axes. 3+2 machining needs to stop and start between each tool reorientation, while 5 axis machining does not require that, so its speed is greatly improved. In addition, 5 axis CNC machining suits are for more applications due to their stronger capacities. Generally, 3+2 machining works for plane processing and can’t complete oblique or special machining, while 5 axis machining center is suitable for various contour surface machining. Try instant online CNC quote in China.

Custom Precision Parts

Contact one of the best metal stamping companies - Tuofa CNC factory now, for free. You would be amazed by our rapid prototype machining.

All information and uploads are secure and confidential with the reliable CNC milling parts manufacturer.

- Tuofa precision CNC machining shop has passed ISO9001 certification

- Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Batch inspection in concurrence with ISO2859

- Strict NDA agreements with all Buyers

- Low-cost on-demand manufacturing, on-time delivery

- We are the top 3D printing company

Instant 5 Axis Machining Quote

Custom 5 Axis CNC Machining Parts

We have experience and right sheet metal fabrication services necessary to bring your idea to life.

This includes services like high tolerance and wide thickness range laser cutting, bending capabilities, CNC machining milling turning, and other post-processing options.

Dimension detail |

Tolerance |

|---|---|

| Edge to edge, single surface | +/- 0.005 inch |

| Edge to hole, single surface | +/- 0.005 inch |

| Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface | +/- 0.030 inch |

| Over formed part, multiple surface | +/- 0.030 inch |

| Bend angle | +/- 1° |

| By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note and specify in your drawing. | |

Material Available

Tuofa as a CNC machining manufacturer offers a wide selection of metal and plastic materials with various color, infill, and hardness options. These materials are matched to an extensive list of manufacturing capabilities to meet the specific requirements of your projects.

Metal CNC Machining Materials

Metals |

Description |

Details |

|---|---|---|

|

CNC Machining Aluminum Alloys: Aluminum 6061, Aluminum 5052, Aluminum 2024, Aluminum 6063, Aluminum 7050, Aluminum 7075, Aluminum MIC-6 |

High strength-to-weight ratio |

|

|

CNC Machining Stainless Steel Alloys: Stainless Steel 15-5, Stainless Steel 17-4, Stainless Steel 18-8, Stainless Steel 303, Stainless Steel 316/316L, Stainless Steel 416, Stainless Steel 410, Stainless Steel 420, Stainless Steel 440C |

Good corrosion resistance + High Hardness |

|

|

CNC Machining Steel Alloys: Steel 1018, Steel1215, Steel4130, Steel4140, Steel4140, PHSteel 4340, Steel A36 |

Good machinability + Excellent electrical conductivity |

|

|

CNC Machining Brass Alloys: Copper 260, Copper 360 |

Good machinability + Excellent electrical conductivity |

|

|

CNC Machining Copper Alloys: Copper 101, Copper C110 |

>99.3% Purity + Superior electrical conductivity |

|

|

CNC Machining Titanium Alloys: Titanium (Grade 2), Titanium (Grade 5) |

Corrosion resistance + High tensile strength |

Surface Treatment of Sheet Metal Processing Services

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

- POM

- Nylon

- ABS

- PEEK

- PTFE

- PC

- HDPE

- PVC

- PMMA

- PET

- PP

Precision machining Applications Industry

Performance-enhancing finishes, precision tolerances as low as +/- 0.001”, and certifiable material options make CNC machining an excellent technology for end-use parts. Start to custom CNC parts online.

Electronic Industry

Medical Industry

Automotive Industry

Agricultural industry

Machine tool industry

Aerospace industry

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home