Is Grade 1 Titanium Good? Comprehensive Guide

Oct 07,2024

Oct 07,2024

Curious to know about the material with exceptional forming properties? In this article, you will learn about grade 1 titanium which manufacturers highly anticipate due to its ductile nature. So, without wasting any time, let’s get to know about its properties, features, and usage in different applications.

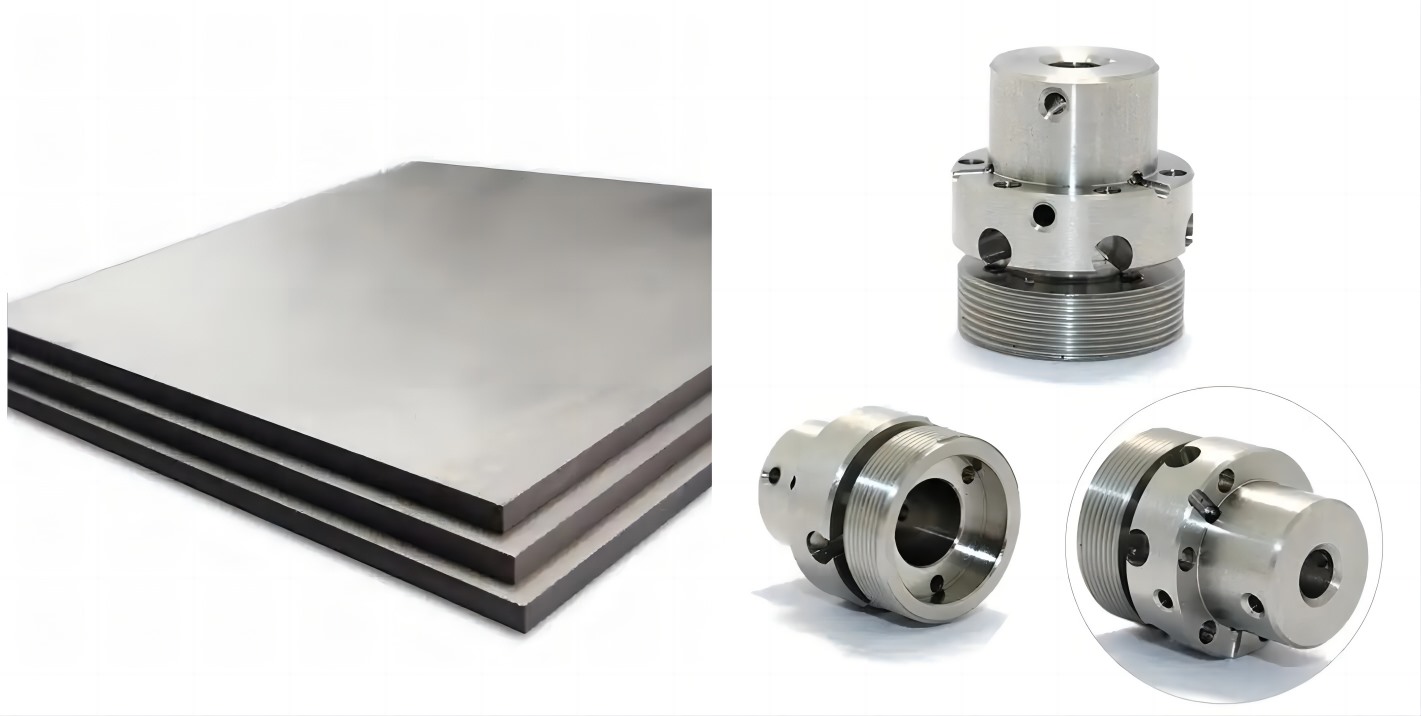

Fig 1: Ti Grade 1

What is Type 1 Titanium?

CP-grade titanium is mainly known for its exceptional formability. This grade is considered the most soft and ductile when compared to other grades of titanium. Moreover, it has good welding properties and shows good resistance against corrosion. Major applications include gaskets, aircraft skin, and other deep drawing applications.

Fig 2: Type 1 Ti

Is Grade 1 Titanium Good?

This grade of titanium is considered best in applications that are prone to high-impact toughness and require high ductile properties.

Grade 1 Titanium Properties

Major properties that belong to this grade of titanium are mentioned below:

- Soft

- Ductile

- Formability

- Corrosion resistance

- Weldability

- High impact toughness

What is Grade 1 Titanium Equivalent to?

| Region | Standards | Names/Terms |

|---|---|---|

| United States | ASTM B348, ASTM B265, ASTM F67, ASME SB-348, ASME SB-265, UNS R50250 | Commercially Pure (CP) Titanium Grade 1, UNS R50250, Titanium Grade 1 |

| Europe | EN 10204 3.1, ISO 5832-2 | Grade 1 Titanium, Ti Gr 1, Commercially Pure Titanium Grade 1 |

| Germany | DIN 3.7025 | Titan Grad 1, CP-Titanium Grade 1, Werkstoffnummer 3.7025 |

| Russia | GOST VT1-0 | Titanium Grade 1, Pure Titanium Grade 1, VT1-0 |

| Japan | JIS H4600 | Titanium Grade 1, Pure Titanium Type 1, JIS Class 1 Titanium |

| China | GB/T 13810, GB/T 3621 | Pure Titanium Grade 1, TA1, Commercially Pure Titanium Grade 1 |

What is Titanium Grade 1 T35 Used for?

Cp grade 1 titanium is mainly used for the following purposes:

- Grade 1 titanium exhaust

- Medical-grade titanium earrings

- Aerospace components

- Bicycle frames

- Fishing gear

- Marine Hardware

Which Grade of Titanium is Best?

Among all the commercially pure grades of titanium, grade 4 Ti is considerably the best due to its exceptional strength, resistance against corrosion, formability, and excellent welding characteristics.

Benefits of Using Grade 1 Titanium

The schematic shows the primary benefits of CP grade 1 titanium:

- High ductility

- Outstanding corrosion resistance

- Heat resistance

- Good strength-to-weight ratio

- Biocompatibility

- Formability

Fig 3: Benefits of Ti grade 1

Different Titanium Grades 1, Grade 2, Grade 3, Grade 4, Grade 5

All these grades are commercially pure with major differences in the amount of strength they possess. Thus grade 1 is the softest while grade 5 is the strongest among the others. Other than that, all these grades have subsequent amounts of corrosion resistance, formability, and welding characteristics.

Corrosion Resistance of Titanium Grade 1

This grade has excellent corrosion resistance and is suitable for applications that are exposed to corrosive environments. Furthermore, this grade shows high resistance against pitting and crevice corrosion.

Try Tuofa Now!

Send drawings to info@tuofa-cncmachining.com

China Tuofa Engineer Support Team

Real human quotes are more accurate than software quotes

Physical Properties

Grade 1 titanium possesses the following physical properties mentioned below:

Density

4.51 g/cm3 is the density for CP grade 1 titanium.

Thermal conductivity

16 W/m-° K is the thermal conductivity for this grade of titanium making it suitable for high thermal performances.

Electrical conductivity

This material has low electrical conductivity and is suitable for applications where conductivity is not a primary requirement.

Titanium Grade 1 Chemical Composition

Below is the chemical composition for grade 1 Ti:

Table 1: Chemical composition

|

Alloying element |

%age composition |

|

Fe |

0.20 |

|

O |

0.18 |

|

C |

0.08 |

|

N |

0.03 |

|

H |

0.015 |

|

Ti |

Balance |

|

Other elements |

0.40 |

How Does the Composition Affect Performance and Properties?

The composition of a certain alloy has a direct influence on its performance as well as its properties. Adding a certain alloying element in the alloy composition allows certain microstructural changes and as a result, it affects the overall mechanical. Physical and thermal properties of that material.

Mechanical Properties of Titanium Grade 1

Below is a brief analysis of the mechanical properties of this grade of titanium:

Hardness

70HB is the hardness value for grade 1 Ti.

Strength

170-310 MPa is the yield strength for commercial grade 1 titanium.

Ductility

This material can elongate up to 24% making this material highly favorable for applications requiring high ductility.

Ultimate tensile stress (UTS) of the lowest and highest

240 MPa is the lower UTS point while 550 MPa is the highest UTS value for grade 1 titanium.

Performance of Grade 1 Titanium at Different Temperatures

This material can maintain its properties at normal as well as elevated temperatures because it has a high melting point. Another reason, this material performs well at variable temperatures due to its good fatigue strength. Overall, a favorable material for manufacturers that require robust material for high-temperature applications.

Applications of Titanium Grade 1

Below are the major applications for grade 1 titanium:

- Aircraft components

- Space applications

- Medical implants

- Surgical tools

- Storage tanks

- Heat exchanger

- Marine Hardware

- Sporting goods

Fig 4: Applications Ti Grade 1

Why Grade 1 is Preferred in Specific Industries Over Other Grades

The reason why certain industries prefer this grade over others is the softness of this grade. It is comparatively very easy to form this grade into various shapes than others. Furthermore, it has good impact toughness, high corrosion resistance, and offers better welding characteristics.

Titanium Grade 1 vs Grade 2

Both grades of titanium are exceptional in their own properties and application usage. If you want a core difference between the two, then it strictly depends on your requirements. If your application desires good formability with excellent corrosion resistance, then grade 1 is suitable, on the other hand, if your application demands high strength along with corrosion resistance, then grade 2 of Ti is more suitable.

Titanium Grade 1 vs Grade 5

The core differences between these grades are mentioned in the table below:

Table 2: Ti Grade 1 vs 5

|

Property |

Ti grade 1 |

Ti grade 5 |

|

UTS (MPa) |

310 |

1000-1190 |

|

Yield strength (MPa) |

220 |

910-1100 |

|

Elongation (%) |

28 |

11 |

|

Hardness (HB) |

120 |

350 |

|

Fatigue strength (MPa) |

170 |

530-620 |

Why Grade 5 is Used in Aerospace and High-Strength Applications

Grade 5 comprises aluminum and vanadium in its percentage composition and is also referred to as Ti 6Al-4V. the main reason behind its usage in aerospace and high-strength applications is due to its several important properties which make this material vulnerable. These properties include lightweight, exceptional corrosion resistance, and maintain its structural integrity even at high temperatures.

Titanium Grade 1 Price and Market Demand

Due to this grade’s exceptional and highly demanding properties, this material is in high demand among several industries. Moreover, the typical price range for this grade lies between $18- 27.

Machining and Welding of Grade 1 Titanium Parts

For welding this grade, the suited techniques include GTAW and PAW; and don’t forget post-weld treatments for the recovery of compromised property.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Commercially Pure Titanium Grade 2 | UNS R50400 Guide

Commercially Pure Titanium Grade 2 | UNS R50400 Guide